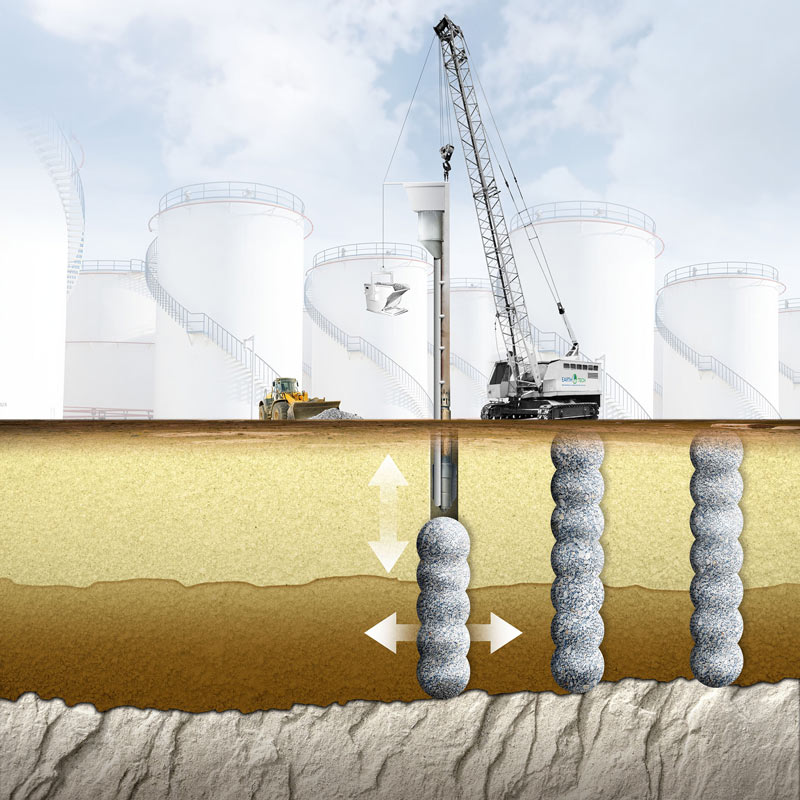

Vibro Replacement (VR) is the process of densifying granular soils and reinforcing cohesive soils with stone columns constructed with the use of specialty down the hole Vibro-Probes.

Installation of the stone columns can be accomplished by using the wet top feed or dry bottom feed installation method.

Wet top feed method: In this method, the Vibro-Probe is hung from a crane and penetrates to the treatment depth under its own weight, vibratory force and water jetting. The densification and reinforcement process is performed from the bottom upward.

During the improvement process, jetting water from the Vibro-Probe tip continues to run, causing water to flush to the surface. The flushing water creates a path for the rock backfill placed at the surface to fall to the base of the Vibro-Probe. The Vibro-Probe is raised a few feet allowing rock to fill the void. The Vibro-Probe is then repenetrated into the rock backfill, densifying the rock and forming a compacted stone column and improved in-situ soil rock matrix. This process is repeated upward in intervals until the stone column is constructed to the surface.

Dry bottom feed method: In this method, a specialty built stone feed tube system delivers the rock backfill to the tip of the Vibro-Probe under compressed air. The process of constructing the stone column is similar to the wet top feed method in that the Vibro-Probe is raised in intervals, from the bottom upward, allowing the stone delivered by the tube to fill the void as the stone column is constructed to the surface.

Applications

- Vibro Replacement is used on sites with variable layers of sands containing silt and clay

- Low to mid rise new construction buildings

- Area loads such as tanks and embankments

- Liquefaction mitigation

- Densification of large areas of clean sand fill, such as dredge sites and lake filling

- Slope stabilization

- Sinkhole triggering and collapsing

Construction Advantages

- Very economical compared to deep foundation systems

- Increased allowable soil bearing capacity reduces the size of foundations

- Expedient process and minimal site disturbance

What to Expect

- Earth Tech will provide a signed and sealed design indicating the treatment plan

- Site clearing and access preparation precede Vibro Replacement

- 2” water source is required for jetting the Vibro-Probe for the wet top feed method

- Depending on site conditions, some surface water control procedures may need to be implemented for wet top feed method

- Large quantities of rock backfill are required, thus site access for rock truck deliveries is needed

- Typically, this work is performed under a performance specification, with minimum improvement criteria specified. Post treatment testing, using SPT’s or CPT’s are used to verify specified requirements. In some cases, load tests are used to verify results.

- Silt and clay spoils can accumulate on the surface using the wet system.

- Final site grading, spoils clean up and foundation construction follow the Vibro Replacement